Stainless Steel Flat Bar, Angle Bar, Round Bar, Hex Bar, Sheet and Tubing

Stainless steel is a corrosion-resistant alloy known for its strength and durability. It's widely used in construction, kitchenware, medical instruments, and industrial equipment.

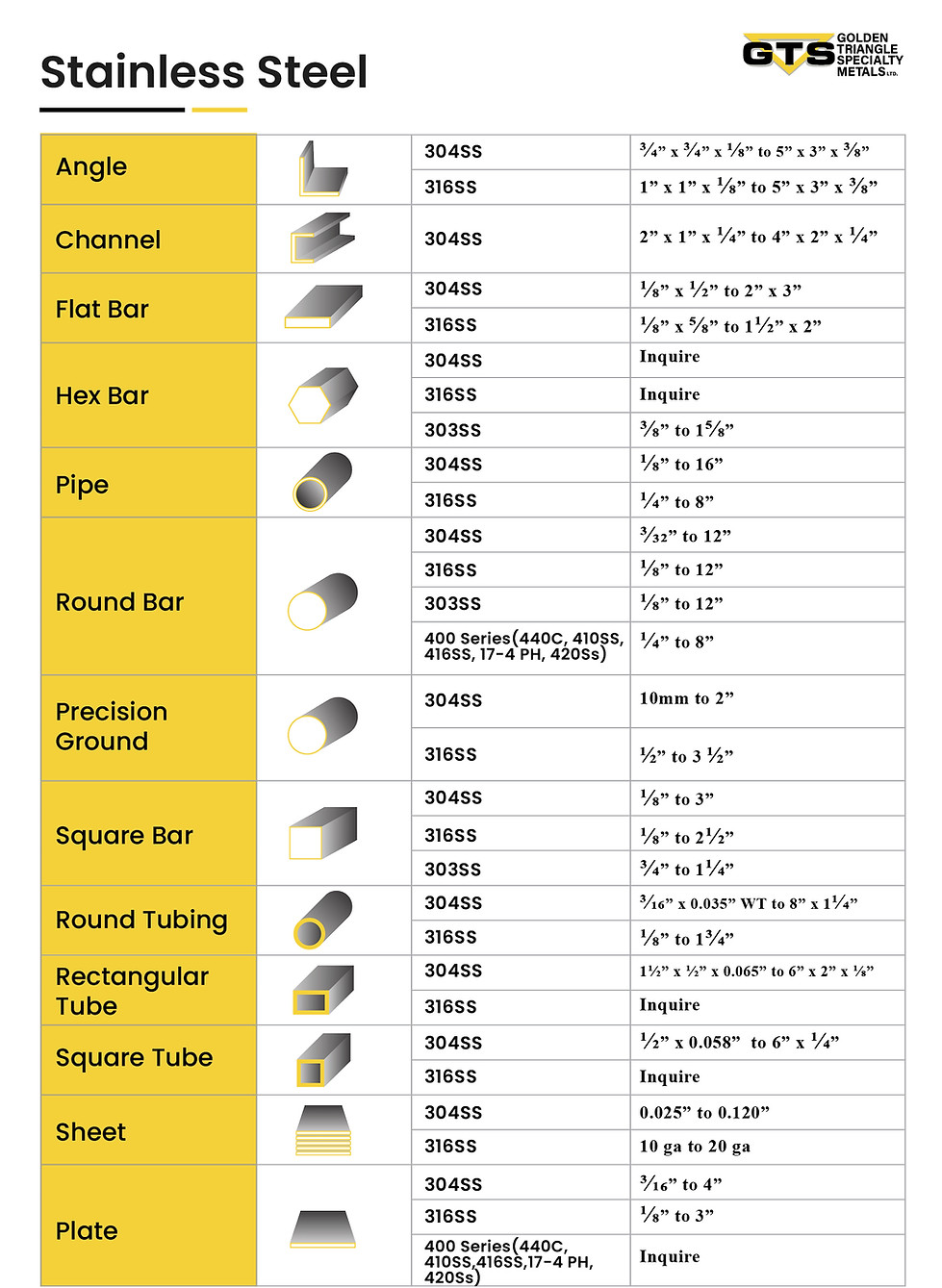

Flat Bar

Stainless steel flat bar offers strength, corrosion resistance, and a clean finish. It’s ideal for structural supports, brackets, and fabrication projects.

Sheets

Stainless steel sheets are corrosion-resistant and easy to form, making them suitable for kitchen, medical, and industrial use.

Angle

The stainless steel angle is a corrosion-resistant structural shape commonly used for bracing, framing, and general support.

Hex Bar

Stainless steel hex bar provides excellent machinability and strength, ideal for precision components and fittings.

Round Bar

The stainless steel round bar offers strength and versatility, making it ideal for shafts, pins, and precision-machined components.

Round Tube

Known for durability and hygiene, stainless steel tubes are used in plumbing, food processing, and structural projects.

Explore Stainless Steel Grades and Their Strengths

304

The most common stainless steel, offering excellent corrosion resistance and good formability. Widely used in kitchen equipment, tanks, and architectural structures.

316

Enhanced with molybdenum for superior corrosion resistance, especially in saltwater environments. Ideal for marine, chemical, and pharmaceutical applications.

303

Designed for improved machinability while maintaining good corrosion resistance. Preferred for precision machining parts like fittings and fasteners.

409

A ferritic stainless steel with moderate corrosion resistance. Commonly used in automotive exhaust systems and applications where weldability is important.

430

Magnetic and corrosion-resistant, often used in appliances, roofing, and food-grade equipment where lower cost is a priority.

17-4 PH

A precipitation-hardened stainless steel offering high strength and moderate corrosion resistance. Suitable for aerospace, chemical processing, and nuclear industries.

2205 Duplex

A high-strength, corrosion-resistant duplex grade used in chemical plants, pressure vessels, and offshore platforms.